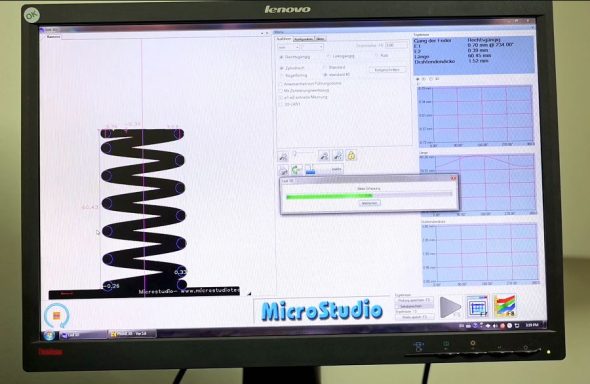

Coiling

Our springs are produced on state-of-the-art CNC-controlled spring coiling machines from machine manufacturers such as Wafios and Simplex Rapid, some of the world's leading manufacturers of machines for the spring industry. These have a camera measuring system with integrated SPC evaluations and 100% control of the spring diameters and/or lengths.

80

Employees

2000 sqm

of production area

60

manufacturing machines

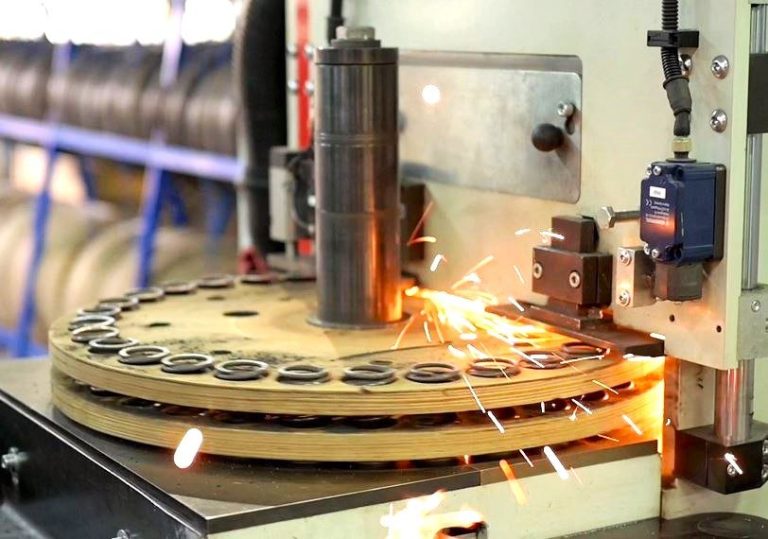

Grinding

Our grinding machines are from the renowned manufacturer G and M Dorn Wire Technology in Hagen.

We offer manual loading or automated feeding for large series.

We always have a large selection of grinding wheels in stock such as CBN grinding wheels, aluminum oxide, aluminum carbide etc. to guarantee you the best results for your product.

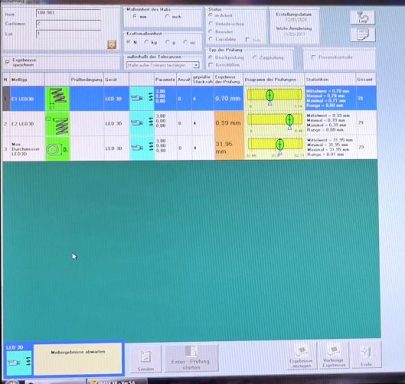

Quality inspection

In order to meet both the specifications resulting from the customer's drawing and our motto "Quality is our trademark", we have the latest testing technology from Böhm and Microsystem in our measuring laboratory in order to be able to carry out all tests accompanying production, document them and make them available to you if required.

Tempering - shot peening

Tempering of compression springs is necessary because the forming of the wire during coiling or bending causes residual stresses that reduce the elasticity properties of the material. These residual stresses are relieved by tempering. All compression springs are tempered between 250° and 480° C, depending on the material used.

Shot peening is a process for surface hardening by compacting the surface. Stresses are generated via the kinetic impact energy of the blasting material, which leads to a hammering of the workpiece surface, while at the same time minimizing surface defects and reducing their effects. This process increases the lifetime of the springs.

Setting and testing systems

Springs are set in order to anticipate any setting behavior that may occur during operation (loss of force due to the unstressed length of the spring being reduced during actuation because the elastic limit of the material used is exceeded). We have automated setting and testing systems in which this process is carried out in conjunction with a 100% test of the spring force at length.

Our offer for you

Consulting

You, the customer, are the focus of our attention. We want you to receive exactly the right product for your application. That is why comprehensive advice, spring design and product optimization are core elements of our work.ent unserer Tätigkeit.

Distribution

We want you to be satisfied with our products. That's why we provide you with advice and support and remain your reliable contact partner from the initial inquiry through to delivery.

Efficiency

Time is money - for our customers too. That's why we work with optimized processes and a well-coordinated team. This enables us to guarantee that we can always serve you promptly and that there are no delays.

Fair prices

Fair prices are the basis for a trustful relationship. That's why our prices are transparent and fair. You tell us your general conditions and we manufacture your product under optimal and customized conditions.

German quality at Bulgarian prices

Qualität

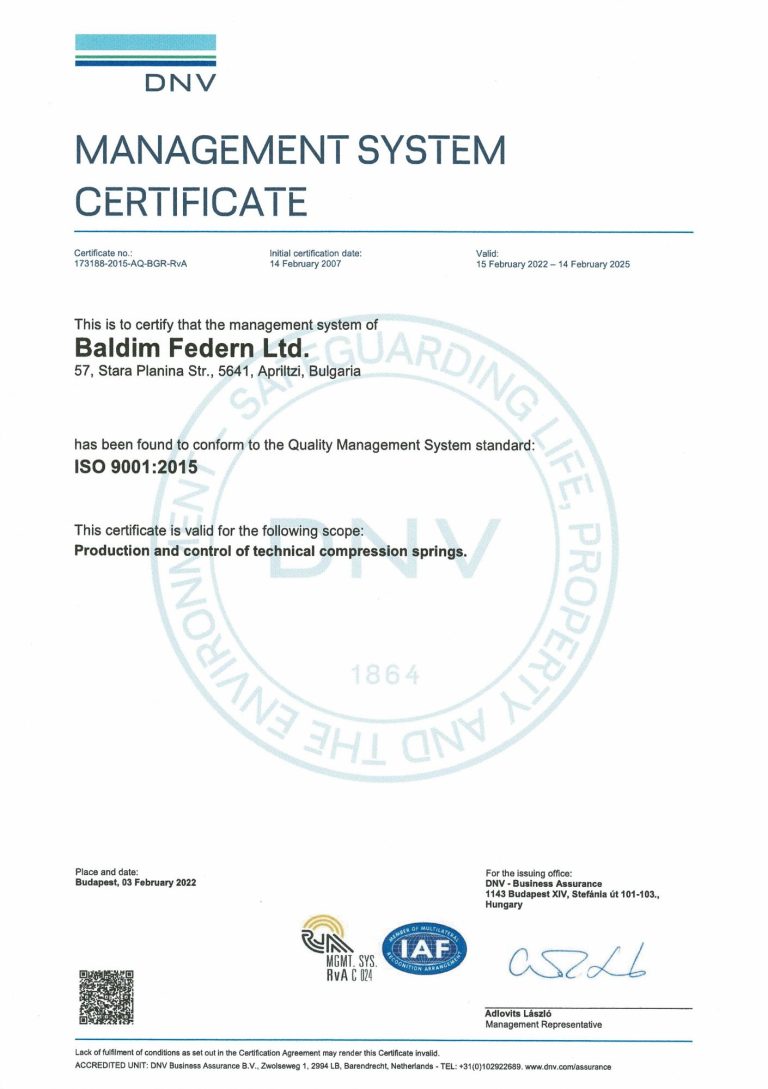

We place the highest value on first-class quality. Only products that meet our high quality standards find their way onto the market. We ensure this quality through regular and extensive product tests and internal and external audits.

We are DIN ISO EN 9001 certified

Zertified since 2004

Urheberrecht ©

Alle Rechte vorbehalten.

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.